ASTM A36 steel plate is one of the most widely specified structural carbon steel grades used in construction and infrastructure projects worldwide. Due to its balanced strength, excellent weldability, and cost efficiency, A36 plate is commonly selected for load-bearing and fabricated components in buildings, bridges, warehouses, and civil structures where reliability and ease of fabrication are critical.

What Is ASTM A36 Steel Plate?

ASTM A36 steel plate is a low-carbon structural steel defined by ASTM A36/A36M standards, offering a minimum yield strength of 36 ksi (250 MPa). It is widely used in construction because it is easy to weld, form, and machine while delivering dependable structural performance.

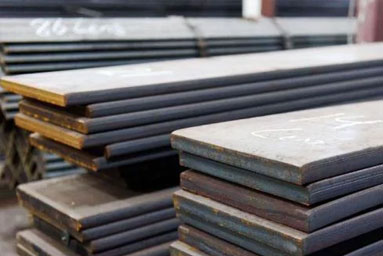

STM A36 Steel Plate – Champak Industries

Why ASTM A36 Plate Is Widely Used in Construction & Infrastructure

In construction projects, material selection is driven by strength, availability, fabrication ease, and cost control. ASTM A36 plate meets all four requirements.

Key reasons contractors and structural engineers prefer A36 plate:

- Predictable mechanical properties for structural calculations

- Excellent weldability with standard electrodes

- Easy cutting, drilling, and forming during fabrication

- Wide thickness and plate size availability

- Cost-effective for large-volume infrastructure projects

These characteristics make ASTM A36 plate suitable for both primary and secondary structural members in commercial and industrial construction.

Construction Challenges That ASTM A36 Plate Helps Solve

Modern construction and infrastructure projects face several material-related challenges:

- Tight project timelines

- On-site fabrication and welding requirements

- Budget sensitivity in large-scale builds

- Need for consistent quality across bulk supply

ASTM A36 plate addresses these challenges by offering uniform quality, fabrication flexibility, and fast availability, reducing project delays and simplifying structural assembly on-site.

Learn more about Champak Industries’ experience and manufacturing background

How ASTM A36 Plate Solves Construction & Infrastructure Requirements

In construction and infrastructure projects, steel plates must perform under static loads, dynamic stresses, fabrication constraints, and site conditions. ASTM A36 plate is engineered to meet these practical realities rather than extreme laboratory conditions.

For builders and EPC contractors, ASTM A36 plate delivers:

- Reliable load-bearing capacity for structural members

- Smooth welding performance without complex pre-heat requirements

- Easy cutting, drilling, and forming during fabrication

- Compatibility with standard construction drawings and codes

- Cost efficiency for large-volume structural usage

This makes A36 plate an ideal solution for time-bound and budget-sensitive infrastructure projects where consistency and workability are as important as strength.

ASTM A36 Plate Applications in Construction & Infrastructure

Below are the 8 most common and proven applications of ASTM A36 steel plate across construction and infrastructure projects:

1️⃣ Structural Beams, Columns & Built-Up Sections

ASTM A36 plates are widely used to fabricate:

- Built-up beams

- Box columns

- Gusset plates

- Load-transfer components

These fabricated sections form the backbone of industrial buildings, commercial complexes, and heavy-duty sheds, where predictable yield strength and weld integrity are essential.

ASTM A36 Steel Plate supply by Champak Industries

2️⃣ Base Plates & Anchor Plates for Buildings

Base plates made from ASTM A36 steel are installed beneath structural columns to:

- Distribute loads uniformly into concrete foundations

- Secure anchor bolts

- Maintain structural alignment

A36 plate is preferred here due to its flatness, machinability, and ability to handle compressive loads without brittle failure.

3️⃣ Bridge Supports & Secondary Structural Members

In bridge construction, ASTM A36 plate is commonly used for:

- Bearing plates

- Bracing members

- Cross frames

- Secondary load-carrying components

While higher-strength steels may be used in critical zones, A36 remains a reliable choice for supporting elements and fabricated parts due to its ease of fabrication and inspection.

4️⃣ Industrial Flooring, Platforms & Mezzanines

Factories, warehouses, and logistics hubs rely on ASTM A36 plates for:

- Equipment platforms

- Walkways

- Stair landings

- Mezzanine floors

These applications demand moderate strength, high weldability, and dimensional accuracy, all of which A36 plate provides.

5️⃣ Trusses, Roof Structures & Canopy Frames

Roof trusses and long-span structures use ASTM A36 plates for:

- Connection plates

- Node joints

- Reinforcement elements

Its ductility allows for stress redistribution under wind and seismic loads, improving overall structural safety.

6️⃣ Embedded Plates in RCC & Precast Structures

ASTM A36 plates are widely used as embedded steel components in:

- Reinforced concrete structures

- Precast wall panels

- Pre-engineered building systems

These plates act as connection points between steel and concrete, ensuring reliable load transfer and long-term durability.

7️⃣ Construction Equipment Frames & Supports

Infrastructure projects often involve heavy equipment such as:

- Batching plants

- Crushers

- Mobile cranes

- Temporary site structures

ASTM A36 plate is commonly used for equipment bases and frames due to its ability to absorb loads and vibrations without cracking.

8️⃣ Architectural & Structural Facade Support

Beyond pure structural use, A36 plates also support:

- Facade frames

- Cladding backplates

- Structural architectural elements

In these applications, A36 offers a balance of strength, formability, and surface finish adaptability.

Technical Properties of ASTM A36 Plate Relevant to Construction

For construction buyers, the most important technical properties include:

- Minimum Yield Strength: 36 ksi (250 MPa)

- Tensile Strength: Typically 400–550 MPa

- Carbon Content: Low, enabling excellent weldability

- Formability: Suitable for bending and rolling

These properties allow ASTM A36 plate to perform reliably in static and dynamic structural environments without complex processing.

ASTM A36 Plate in an Industrial Warehouse Project

In a typical industrial warehouse project:

- A36 plates are used for base plates and fabricated beams

- Welded connections are completed on-site without special pre-heating

- Plates are cut and drilled to match project drawings

- Structural assembly proceeds faster due to fabrication ease

This reduces construction downtime and ensures smoother coordination between design, fabrication, and erection teams.

ASTM A36 Plate vs Other Structural Steel Options

While ASTM A36 plate is widely used, it’s important to understand where it fits:

- ASTM A36 Plate: Ideal for standard structural loads and general construction

- High Tensile Plates: Used where higher strength-to-weight ratios are required

- Abrasion Resistant Plates: Preferred in wear-intensive infrastructure zones

For applications involving high wear or heavy stress, Champak Industries also supplies complementary grades through its extended portfolio.

Supporting reference: High Tensile Plates

Supporting reference: Abrasion Resistant Plates

Why Source ASTM A36 Plate from Champak Industries

When sourcing ASTM A36 plate for construction and infrastructure, reliability of supply is as critical as material quality.

Champak Industries offers:

- Consistent ASTM A36 plate quality

- Wide thickness and size availability

- Cut-to-size and project-based supply support

- Documentation and traceability

- Experience serving construction and infrastructure clients

ASTM A36 Plate Supply, Cutting & Delivery for Construction Projects

Construction and infrastructure projects demand timely material availability and dimensional accuracy. Delays in plate supply can directly impact project timelines and costs.

Champak Industries supports construction buyers with:

- ASTM A36 plates in standard and project-specific sizes

- Thickness ranges suitable for light to heavy structural use

- Cut-to-size, profiling, and fabrication-ready supply

- Bulk quantity handling for infrastructure-scale projects

- Reliable logistics for domestic and export deliveries

This ensures your structural steel reaches site ready for fabrication and installation, reducing rework and downtime.

Contact for project supply & delivery support

Buyer Selection Guide — Choosing the Right ASTM A36 Plate

Before finalizing ASTM A36 plate for construction use, buyers should evaluate the following:

- Load requirement: Confirm plate thickness based on structural calculations

- Application type: Base plates, beams, embedded plates, or platforms

- Fabrication method: Welding, drilling, cutting, or bending requirements

- Surface condition: As-rolled or processed finish

- Compliance: ASTM certification and mill test documentation

For applications involving higher loads, wear, or aggressive service conditions, it may be advisable to evaluate alternative grades alongside A36.

Explore related structural and specialty plates

ASTM A36 Plate – FAQ’s

1) What is ASTM A36 plate mainly used for in construction?

ASTM A36 plate is mainly used for structural beams, columns, base plates, platforms, embedded plates, and fabricated supports in buildings, bridges, warehouses, and infrastructure projects.

2) Is ASTM A36 plate suitable for load-bearing structures?

Yes. ASTM A36 plate offers a minimum yield strength of 36 ksi, making it suitable for standard load-bearing structural applications when designed as per engineering requirements.

3) Can ASTM A36 steel plate be welded easily on site?

ASTM A36 steel plate has excellent weldability and can be welded using standard electrodes and procedures without special pre-heating in most construction applications.

4) What thickness of ASTM A36 plate is commonly used in construction?

Common thicknesses range from 6 mm to 100 mm or more, depending on whether the plate is used for base plates, beams, platforms, or embedded structural elements.

5) Is ASTM A36 plate used in bridge construction?

Yes. ASTM A36 plate is widely used in bridge supports, bracing members, bearing plates, and secondary structural components where moderate strength and easy fabrication are required.

6) When should a buyer consider alternatives to ASTM A36 plate?

Buyers should consider high tensile or abrasion-resistant plates when projects involve heavy loads, high stress, or severe wear conditions beyond standard structural requirements.

Get a Quote — ASTM A36 Plate for Construction & Infrastructure

If you are planning a building, industrial facility, warehouse, bridge component, or infrastructure project, sourcing the right ASTM A36 plate is critical to structural safety and cost control.

Request pricing, availability, or technical guidance

View ASTM A36 Steel Plate specifications

ASTM A36 Plate — A Reliable Foundation for Modern Construction

ASTM A36 steel plate remains a trusted structural material in construction and infrastructure because it delivers strength where required, flexibility during fabrication, and cost efficiency at scale. When sourced from an experienced supplier like Champak Industries, A36 plate becomes more than just a material — it becomes a dependable foundation for long-term structural performance.