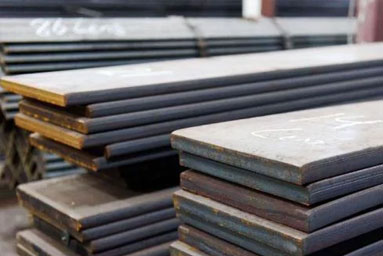

Looking for steel plates that reach peak performance under severe wear and impact? Manganese X120Mn13 Plates offer unmatched durability. These high-manganese steel plates self-harden under stress, making them ideal for rugged industrial environments.

What Are Manganese X120Mn13 Plates?

Manganese X120Mn13 is a high-manganese (11–14 %) austenitic steel plate known for its work-hardening properties. As it undergoes repeated impacts or abrasion, the surface becomes harder while maintaining a tough core, making it a top choice for wear-resistant applications.

Explore more:

🔗 Product Range

🔗 Manganese X120Mn13 Plates & Sheets

Why It’s Crucial in Industrial Applications

These plates are vital where extreme conditions prevail—they:

- Work-harden rapidly, boosting abrasion resistance with use

- Withstand high-impact wear without crumbling

- Maintain ductility and strength for shock absorption

- Resist wear even in unlubricated or contaminated environments

Typical sectors include crushers, shot-blasting machines, and heavy-duty transport equipment.

Trends, Challenges & Common Buyer Questions

Professionals in mining, cement, and engineering often ask:

- How does X120Mn13 compare with other wear-resistant steels?

- What dimensions and treatments are available?

- Can these plates be cut, welded, or machined?

- What supply and export documentation is available?

This blog addresses these questions and shows how Champak Industries delivers trusted, certified quality.

Check out our blog here:

🔗 Champak Industries Blog

How Champak Industries Supplies X120Mn13 Plates

At Champak Industries, we supply X120Mn13 Manganese Plates that meet global standards for wear resistance and impact toughness. Our plates are preferred by buyers in mining, cement, quarrying, and heavy engineering because we provide:

- ✅ High-quality manganese content (11–14 %)

- ✅ Plates that self-harden under impact and abrasion

- ✅ Wide range of sizes, thicknesses, and custom cut-to-length options

- ✅ Test certificates and compliance documentation

- ✅ Export-ready packaging for global supply

🔗 Explore Manganese Plates & Sheets

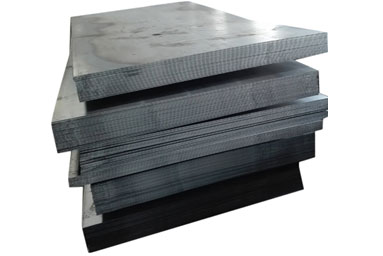

Key Applications of X120Mn13 Plates

Mining & Quarrying Equipment

- Liner plates for crushers and hoppers

- Chutes, skips, and conveyor systems exposed to impact and abrasion

Cement & Aggregate Industry

- Impact surfaces in cement mixers

- Heavy-duty loaders and transfer points

Railway & Earthmoving

- Crossing points, ballast tampers, and excavation machinery

- Buckets and blades for earthmoving equipment

Foundries & Shot Blasting

- Blast cabinets and wear plates in foundry environments

- Protects against steel shot and grit erosion

Technical Specifications of X120Mn13 Plates

| Parameter | Specification |

|---|---|

| Grade | X120Mn13 (High Manganese Steel) |

| Manganese Content | 11–14 % |

| Tensile Strength | ~900 N/mm² (after work-hardening) |

| Yield Strength | ~350 N/mm² |

| Hardness (As Delivered) | ~200 HB |

| Hardness (Work-Hardened) | Up to 600 HB |

| Thickness Range | 5 mm – 100 mm |

| Condition | As Rolled / Annealed |

🔗 Manganese Steel Plates Overview

Champak vs Generic Suppliers – Why Quality Matters

| Feature | Champak Industries | Generic Suppliers |

|---|---|---|

| Manganese Content | 11–14%, guaranteed | Often inconsistent |

| Hardening Ability | Up to 600 HB (proven) | Lower hardness achieved |

| Customization | Cut-to-size & ready-to-install | Standard only |

| Documentation | COA, Mill Test Reports | Often missing |

| Export Packaging | Palletized, seaworthy | Basic bulk packing |

Why Choose Champak Industries for X120Mn13 Plates

- 🏭 Trusted stockist & supplier with years of industry experience

- 📦 Cut-to-size, export-ready supply

- 📄 Full certification & traceability for every batch

- 🌍 Serving domestic and international clients

- 💬 Responsive support for mining, cement, and engineering industries

Export Destinations & Packaging Options

At Champak Industries, we supply X120Mn13 Manganese Plates to industries across India and export markets worldwide.

📦 Packaging Options:

- Standard bundles with steel strapping

- Palletized & seaworthy export packaging

- Custom cut-to-size & protected with plastic wrapping

- Bulk container loads for overseas shipments

🌍 Export Reach:

- Widely shipped to mining, cement, and construction hubs in Asia, GCC, Africa, and Europe

- Compliant with international shipping norms

- Every batch supplied with Mill Test Certificate (MTC) and compliance documents

🔗 Contact Us for Export & Packaging Details

How to Select the Right Manganese Plate

| Selection Factor | Recommendation |

|---|---|

| Impact Resistance Needed | Choose X120Mn13 for crushers & heavy impact zones |

| Abrasion & Wear Resistance | Opt for plates in high-thickness ranges |

| Weldability Requirement | Pre-heating recommended for welding applications |

| Customization | Ask for cut-to-size & annealed supply |

| Export Compliance | Ensure MTC & packaging certificates are included |

FAQs

- What are Manganese X120Mn13 Plates used for?

They are used in crushers, shot-blasting machines, mining equipment, and earthmoving applications. - What is the hardness of X120Mn13 plates?

They start at ~200 HB and work-harden up to 600 HB under impact. - Can X120Mn13 plates be welded?

Yes, with proper technique — pre-heating and special electrodes are recommended. - Are X120Mn13 plates suitable for quarry crushers?

Absolutely. They are one of the most preferred liner materials for crushers and hoppers. - Do you supply cut-to-size manganese plates?

Yes, Champak Industries provides cut-to-size, ready-to-use plates. - Is certification provided with the plates?

Yes, all plates come with Mill Test Certificates and compliance documents. - What industries use X120Mn13 plates?

Mining, cement, railways, foundries, earthmoving, and heavy machinery. - Where can I buy Manganese X120Mn13 plates in India?

Directly from Champak Industries with global delivery support.

🔗 See More Resources on Our Blog

Get Quote or Technical Support

Looking for a reliable source of Manganese X120Mn13 Plates?