What is Corten Steel

The term corten refers to the two distinctive characteristics of the steel: (COR) corrosion resistance and (TEN) tensile strength. Corten Steel (sometimes referred to as weathered steel) is an assembly of steel alloys that are frequently used in external construction. It is functionally designed to reduce the need for painting and if left outside, exposed to the elements, they will build up a rusted look in just a small period of time.

Corten Steel is copper chromium alloy steel that alloys display a greater level of resistance to atmospheric weathering when compared to other unalloyed steels. This is due to the steel forming a defensive layer on the surface under the influence of the weather conditions.

The corrosion-retarding effect of the defensive layer is created by the accurate distribution and concentration of alloying elements present in it. The layers protecting the surface develop and regenerate constantly when subjected to the influence of the weather conditions. In simple words, the steel is allowed to rust in order to create the “defensive” coating.

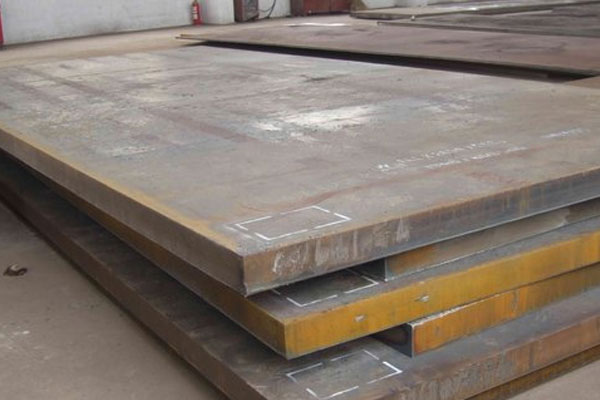

Corten Steel Manufacturing procedure

The corten steel manufacturing procedure starts with a unification of three major plates of steel i.e. copper, chromium, and nickel, along with other alloying elements such as phosphorus, silicon, and manganese. Small amount of carbon is used during the blending procedure—less than 0.2-0.3 percent, to ensure strength, malleability, and toughness.

Combining these particular metals and elements results in a 1/4th inch dense sheet that is sufficiently flexible to be produced in almost any desired shape. The real magic of the corten steel procedure, however, happens after the primary mixing takes place and during its natural weathering cycle.

How does Corten Steel Rust

Corten steel is alloy steel manufactured by adding chromium, phosphorus, copper and nickel-molybdenum. These alloys amplify the corten steel’s resistance to atmospheric corrosion by producing a protective patina on the surface. This patina generally forms in one to three years, depending on the weather conditions and the alternation of dry and wet periods that help the patina adhere. Due to the existence of phosphorus, this defensive layer regenerates constantly on the surface and forms a barrier against pollution, oxygen and moisture.

Welding of Corten Steel

The Welding process of Corten steel can be slightly difficult, but with the accurate preparation, it can be done without any troubles.

The first step is to preheat the metal when dealing with solid plates. This will help to avoid any warping or cracking during the welding procedure. Once the metal is hot, the welding can be easily started. Make sure to utilize a gas lens cup to help protect the weld from the wind when using TIG welding.

What are the Properties of Corten Steel

Corten steel can be bent, shaped or welded so perfectly for an extensive range of fabrications. Cor-ten is a very strong steel with a characteristic yield strength of 345 Re MPa, tensile of 485 Rm MPa and minimum elongation of 20 A80%.

Advantages of Corten Steel

Corten Steel has many Advantages including maintenance and durability. Along with high-strength, Corten steel is a very low maintenance steel that is perfect for structures where maintenance is difficult or risky like bridges, or where interference needs to be reduced such as around main roads or railways.

Corten steel is constructed more rapidly than other kinds of steel since procedures like painting can be eliminated. The rust appearance that develops on Corten Steel can amplify the durability of the application given the resistance to corrosion hence producing a more efficient resolution.

Application & usage of Corten steel

Corten steel finds application particularly in public spaces (street furniture), building (architecture and construction) or to make up market works of art, signs, chimneys and fire bowls.

Corten steel is also called weathering steel. The COR comes from corrosion resistance and the TEN from tensile strength. In short, this material can endure wind and rain. The reason for this is in the unique rust coating.