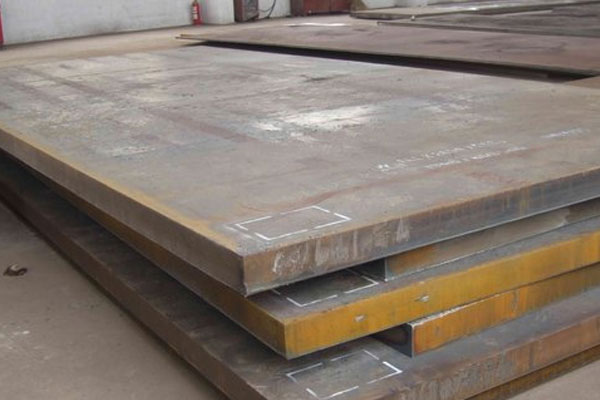

What are Wear-Resistant Steel Plates?

Wear resistant steel plates, also named abrasion-resistant plates (AR Plates), are used to decrease wear and tear on equipment surfaces caused by extreme rolling abrasion and influence. The strength of these wear-resistant steel plates is improved by heat treatment such as quenching and tempering, or by addition of some alloying elements, the unique characteristics of the steel plates are exaggerated.

What Factors will Affect the Quality of Wear-Resistant Steel Plates?

Factor 1: Heat Treatment & Alloy Content

Wear-resistant steel plates are well-defined regarding their hardness. There are mostly two ways to increase the hardness and durability of the wear plates:

i. Heat Treatment (QT)

For some particular working environments, such as mining and earthmoving, quenched and tempered steels by the procedure of heat treatment are an economical choice. However, these types of wear plates, while cost effective, are not as tough as alloy wear plates.

ii. Adding Alloy Content

For alloy wear plates, there are three basic alloying elements: silicon, carbon, manganese, and of course, other alloying elements can also enhance different mechanical performances of wear-resistant steel plates:

- Carbon: The increase of carbon content in steel will enhance its yield point and tensile strength but decrease its ductility and influence. Meanwhile, too much carbon content could decrease the weldability of the steel, so adjusting the carbon content balance in the wear plate is a very vital operation that can’t be ignored.

- Silicon: Silicon can significantly increase the elastic limit, yield point and tensile strength of steel, but like carbon, the weldability of steel would reduce by adding too much content of silicon.

- Manganese: Manganese is a good deoxidizer, and desulphurization in the steelmaking procedure, so that the wear plate has better strength and hardness, also enhances the hardenability of steel and the hot processing performance.

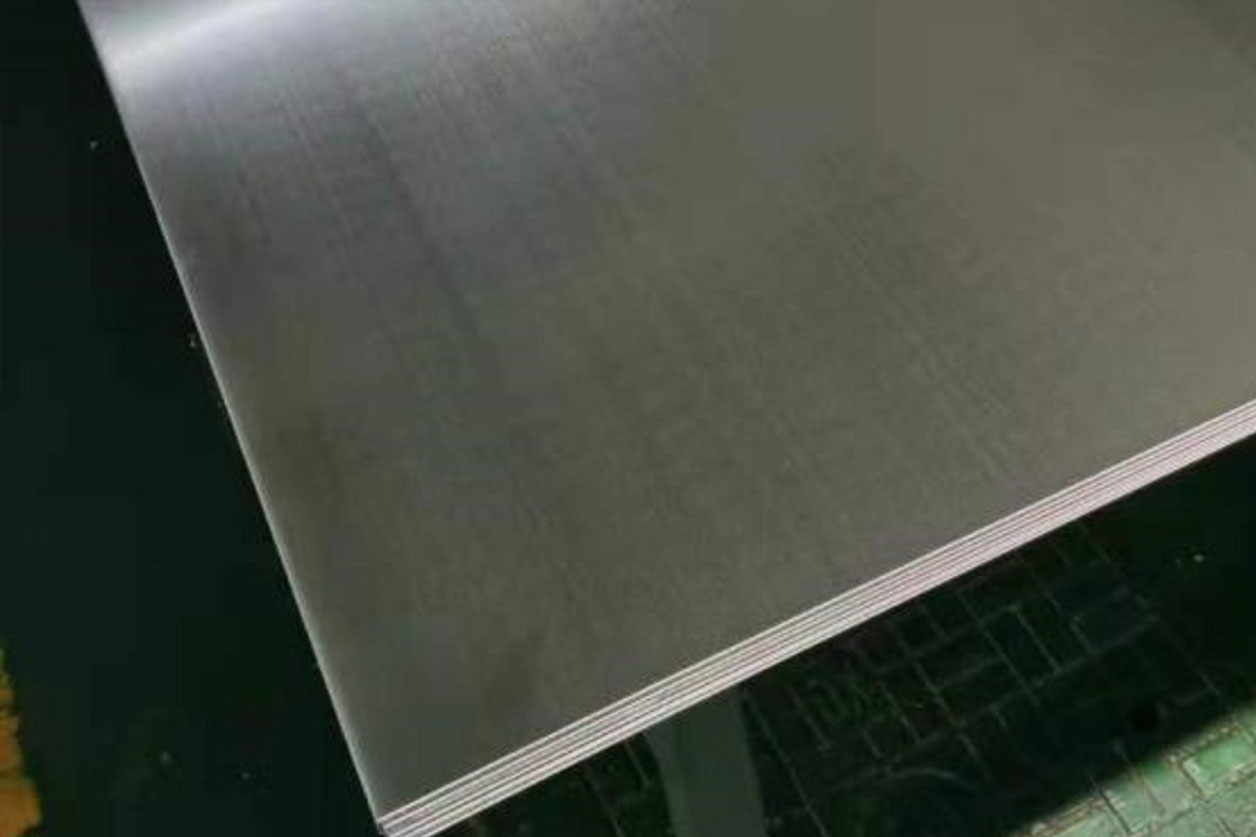

Factor 2: The Smoothness of the Surface

When considering the lifecycle of the wear-resistant steel plates, particularly in applications like the conveyor belts, truck bodies, and fan blades, the smoothness of the surface is a very acute factor. A smooth surface can ensure constant wear as well as bending radius, which can deliver an accurate bending precision.

Factor 3: Rigidity Variations within the Plate

The essential hardness value affects the lifetime of the wear parts, for example, as wear occurs and new material is exposed, if the core rigidity value of the steel plate is greater, the wear rate will be reduced compared to the steel plate with a low core hardness value, and the service lifespan of the parts will also be extended.

Manufacturing Process of Wear Resistant Plates

Wear Resistant Plates is an alloy of carbon, iron ore, and other elements like manganese and chromium. The iron is melted in a blast furnace to eliminate impurities, and alloying materials (including carbon) are added during that procedure. The added elements help the steel resist wear even with extended rubbing. Other substances are added to stop oxidation. The melted steel is then shaped, heat treated and cut.

The resulting chemical composition has numerous components that help it resist abrasions. Carbon adds strength and toughness. Chromium and manganese limit the steel’s response to wearing. Heat treatment helps the steel form tough microstructures that increase hardness.